- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Как се произвеждат LCD и сензорен панел?

Here's an introduction written from a professional LCD and Touch Panel manufacturer's perspective, to let you know our key processes to assure customers of quality and reliability:

The Automated Journey of Your LCD & Touch Panel Modules

At Victronix, we pride ourselves on manufacturing the highest quality LCD modules and capacitive touch panels (CTP) through a fully automated production process. Our commitment to technological excellence ensures consistent performance, durability, and timely delivery for your critical applications. Here's a glimpse into our advanced manufacturing journey of TFT LCD and CTP:

1.Building the Foundation: Panel & Glass Processing (POG)

Your display begins with precision-cut LCD substrate glass. Our automated lines handle ultrasonic cleaning, rigorous electrical testing, and the critical lamination of polarizers in a dust-free workshop. Advanced debubbling and final electrical checks guarantee a flawless base panel.

2.Integrating Intelligence: Circuit Bonding (FOG)

The "brains" of your module are added here. Automated equipment performs delicate plasma cleaning, precisely bonds driver ICs and Flexible Printed Circuits (FPCs) using Anisotropic Conductive Film (ACF), and conducts Automated Optical Inspection (AOI) for microscopic particles. Every connection undergoes thorough electrical testing before sealing for protection.

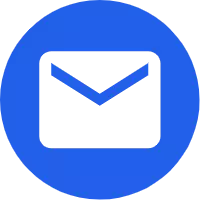

3.Assembling the Module: LCM Process

Our automated systems handle precise backlight unit assembly, integration of the touch panel, soldering, and tab attachment. Rigorous electrical and optical testing in controlled environments ensures perfect display function and touch response.

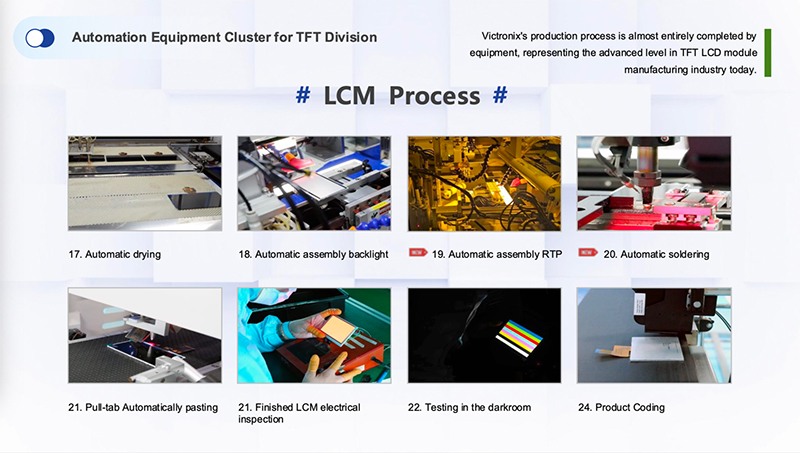

4.Touch Panel Process (CTP)

For touch modules, this stage is crucial. Sensors undergo plasma cleaning and precise ACF/FPA bonding. Capacitive screens are electrically tested and programmed. The cover lens is optically bonded (OCA), meticulously debubbled, scribe-tested for strength, and cured with UV solidification for ultimate durability and clarity.

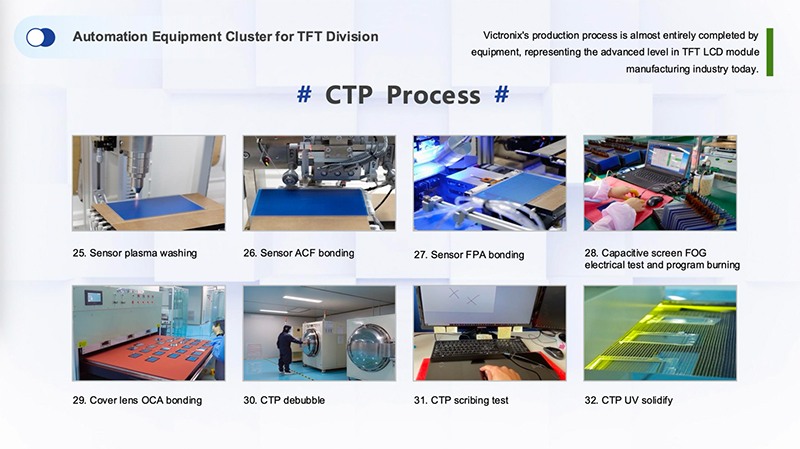

5.Ensuring Perfection: Final Assembly & Packing

Every module receives meticulous attention. Cover lenses are inspected and cleaned, followed by final optical bonding (LCM). Accessories are assembled, and the product undergoes stringent Outgoing Quality Control (OQC). Protective films are applied, modules are wrapped with care, packed securely, and readied for shipment to you.

Why Victronix Automation Matters for You:

●Unmatched Consistency: Robotic precision eliminates human error at every step.

●Enhanced Quality: In-process testing (electrical, AOI, optical, darkroom) catches defects early.

●Superior Reliability: Controlled processes like plasma cleaning, UV curing, and precise bonding ensure long product life.

●Scalability & Speed: Automated lines deliver high volumes without compromising quality, meeting your demand.

●Advanced Technology: We represent the cutting edge in TFT LCD and touch module manufacturing.

From raw glass to your finished product, Victronix leverages seamless automation to deliver TFT LCDs and touch panels you can trust for performance and quality. We engineer reliability into every step.